FUEL STORAGE

The DLRA is required to manage risks from hazardous chemicals to health and safety so far as reasonably practicable including those operating temporary fuel storage and handling systems at Speed Week.

This event is attended by relatively large numbers of the of the general public who have access to the pit area and we are obligated to ensure their safety.

This document is based upon the Work Health and Safety Regulations 2012 (SA)

- Risk management

- General controls

- Separation distances

- Control of ignition sources

- Spill containment systems

- Fuel dispensers

- Firefighting equipment

- Administrative controls

- Emergency Plans

- Glossary

- Further information

Risk management

The DLRA will identify the risks of all the chemicals on site and manage them in relation to transport, storage, use and disposal and maintain them in a register.

Vapour from flammable fuels such as unleaded, E10 or E85 petrol or liquids assigned to UN number 1203 may mix with air, creating an explosive atmosphere.

Failure to control ignition sources can result in a fire or explosion, putting the health and safety of workers and patrons at events at serious risk of injury. Fire or explosion may also result is severe property damage.

Ignition sources may include naked flames, mechanical or static sparks, non-rated electrical equipment or hot surfaces.

AS60079: Part 10.1 provides a methodology for identifying potentially explosive atmospheres and a range of example hazardous areas for fuel systems.

Australian Standards such as AS1940, also include example ways for storing and handling fuels safely.

Applying traditional ways of managing risks to health and safety to a temporary fuel system may not be possible or reasonably practicable in all circumstances.

Please note that some hazard classes and categories are excluded by the WHS Regulations and therefore the Code does not apply to those chemicals.

Refer to page 3 of the Managing risks of hazardous chemicals in the workplace - Code of Practice for more information on exclusions.

General controls

- A register of safety data sheets (SDSs) for fuels stored or handled at Speed Week shall be readily available at all times.

- A fuel’s SDS shall be taken account of when identifying hazards and controlling risks.

- Bulk fuel tanks, dispensers and package stores shall be located in a dedicated fuel compound isolated from public areas by barriers such as 1.8m high chain-wire fencing.

- Fuel compounds shall be provided with a minimum of 2x entry/exit points fitted with unobstructed outward opening gates and unauthorised access shall be restricted.

- Plant and equipment shall be designed and manufactured for its intended purpose including road tankers connected to fuel dispensers, IBCs connected to decanting systems or dispenser used to fill drums >25L.

- Road tankers shall be disconnected and isotainers removed from a prime mover prior to being connected to any fuel dispensing system.

- Tanker trailers and isotainers connected to a dispensing/decanting system via flexible hoses shall be fitted with a remotely controlled emergency shut-off valve as close as possible to the tank’s outlet. Operating this valve shall be possible from outside a tank’s spill compound and at any dispensing or decanting point.

Note: The purpose of this valve is to provide a means of remotely closing a tank outlet in the event of a hose failure between a bulk tank and dispenser. - Temporary fuel tanks shall not exceed 50,000L.

- Temporary package stores containing fuels shall not exceed 10,000L.

- Any IBC connected to a fuel decanting system shall be considered a bulk tank and therefore, be consistent with the requirements of AS1940 and AS1692 for aboveground tanks.

Separation distances

Separation distances slow the escalation of a fire involving flammable liquids and must be applied as described to temporary fuel storage at short term events.

The below provides guidance about separation distances:

- Aboveground bulk tanks shall be separated from public areas, vehicle garages, buildings, property boundaries, accumulations of combustible materials or other fire-risk dangerous goods as per Table 5.4 of AS1940, (e.g. 42,000L fuel tank = 12m). Note: The size of a road tanker shall be considered the aggregate of all compartments.

- Any two stand-alone bulk fuel tanks shall be separated by >1m.

- Package stores shall be separated from public areas, vehicle garages, buildings, property boundaries and accumulations of combustible materials or fire-risk dangerous goods as per Table 4.1 of AS1940 or 3m, whichever is greater, e.g. 20 x 200L fuel drums = 5m minimum separation distance.

- Aboveground bulk tanks and package stores shall be separated from each other as per Table 5.3 of AS1940.

- Fuel dispensers shall be located outside of enclosed buildings in well ventilated areas and >8m from any aboveground non-fire rated bulk tank or package store containing flammable liquid.

- Fuel dispensers shall also be located outside of any spill compound for a bulk fuel tank or package store.

Control of ignition sources

Entrants must control ignition sources and accumulation of flammable and combustible substances.

Temporary fuel systems must be adequately protected from undesirable static electricity accumulation.

Ensure ignition sources are eliminated from any on-site hazardous area(s) during anytime a potentially explosive mixture of flammable vapor and air exists.

Hazardous areas around bulk fuel tanks, dispensers and package stores shall be identified on a plan or by erecting signs such as ‘No Smoking, No Ignition Sources’ around the perimeter of such areas.

Ensure electrical equipment located within a hazardous area is appropriately certified for the corresponding zone and protection type required.

Spill containment systems

Entrants shall provide secondary spill containment or bunds for aboveground bulk tanks or package stores in excess of minor storage.

Spill compounds shall be constructed from non- combustible materials such as concrete, steel or earth.

Spill compounds for bulk tanks shall be capable of containing >100% of the largest tank within a spill compound. Note: Spill compounds for bulk tanks with multiple compartments shall be able to contain 100% of any compartment connected to a dispenser.

Spill compounds for package stores shall be capable of containing 100% of the largest package plus 25% of the aggregate of all packages within the compound e.g. 20 x 200L drums = a spill compound >1200L.

Fuel dispensers

Dispensers for filling vehicles shall be consistent with section 7.3 of AS1940.

Fuel dispensing shall be carried out by suitably trained personnel only.

Entrants dispensing fuel must have access to a spill kit.

Firefighting equipment

Package stores shall be provided with 1 x 9 kg ABE and 1 x 9kg foam extinguisher within 10m.

Dispensers shall be provided with 2 x 9kg ABE fire extinguishers within 10m.

Bulk tanks with a capacity <10,000L shall be provided with 1 x 9kg ABE and 1 x 9kg foam extinguisher within 10m.

Bulk tanks with a capacity >10,000L shall be provided with 1 x 20,L foam concentrate-equipped hose reel within 10m. Alternatively, where a reticulated water supply is not readily available, provide a 40kg wheeled foam extinguisher or:

- firefighting pump

- water tank >2000L capacity

- sufficient foam concentrate, and

- a trained crew on standby.

Only compatible foams shall be provided.

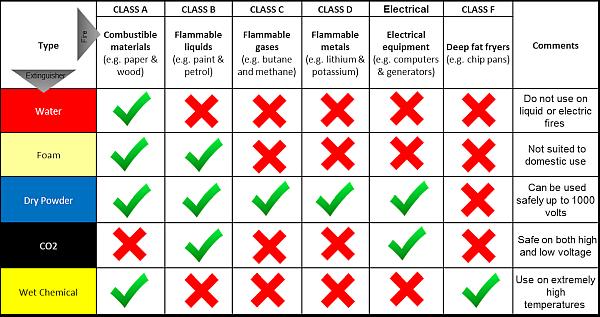

NOTE: All entrants must have a fire extinguisher appropriate for the type of fuel they are using or storing.

Approved fire extinguishers

| Fuel | Class | Type of Extinguisher | ||

| Petrol | B | Foam Extinguisher (AFFF), ABC Fire Extinguishers, Carbon Dioxide fire extinguishers | ||

| Diesel | B | Foam Extinguisher (AFFF), ABC Fire Extinguishers, Carbon Dioxide fire extinguishers | ||

| Methanol | A | If there is a methanol fire, just plain water is effective as long as there is not also gasoline, diesel fuel or engine lube oil involved in the combustion. A dry chemical fire extinguisher is preferred over a CO2 extinguisher. Note: with a Methanol fire, there is no light, no smoke and very little infrared radiation. Methanol is highly toxic if ingested. |

||

| Nitromethane | A | Nitromethane fires can be extinguished with water. Unlike gasoline and oil fires, water, when carefully applied, will not spread Nitromethane fires, so you may use water as an extinguisher. Nitromethane fires may also be extinguished with carbon dioxide or foam. Dry-chemical tri-class extinguishers that contain only ammonium phosphate are suitable for small Nitromethane fires. | ||

| Nitrous Oxide | On it's own Nitrous Oxide is not flammable. It will accelerate combustion and increase the risk of fire and explosion in combustible and flammable materials. However it is stored under pressure and containers may fracture and burst, providing a high volume of accelerate. | |||

| LPG or Propane | C | Dry powder chemical extinguishers | ||

| Acetylene | C | Dry powder chemical extinguishers |

Administrative controls

The filling of bulk tanks or IBCs not fitted with vents as per AS1940 (i.e. >4m from ground level and >150mm above the top of the tank), shall be prohibited.

Adequate information, training and instruction about a temporary fuel storage and handling system’s hazards and the controls in place to minimize their risk shall be provided to entrants and teams.

Ensure bulk fuel tanks and package stores are placarded in accordance with schedule 13 of the Work Health and Safety Regulation 2011.

Notify the State Authority as a manifest quantity workplace for any temporary fuel system in excess of 2500L

Emergency response and evacuation procedures shall be documented.

Provide a manifest in a red weather proof container at the registration caravan.

Emergency plans

The DLRA has prepared an effective emergency plan for the workplace. The purpose of the emergency plan is to plan for, and thus minimize, the effects of any dangerous occurrence or near miss at a workplace resulting from the handling and storage of hazardous chemicals.

Glossary

ADG Code: the Australian Code for the Transport of Dangerous Goods by Road and Rail.

Bulk tank: a fuel storage tank with a water capacity >500L designed to be connected to a decanting or dispensing system and includes an IBC connected to a decanting system.

Fire-risk dangerous goods: includes classes 2.1, 4 or 5.

IBC: an intermediate bulk container approved under the ADG Code.

Isotainer: a portable bulk tank approved under the ADG Code to transport fuel.

Minor storage: are those quantities less than Table 2.1 of AS1940.

Package: a portable container or drum approved under the ADG Code.

Package store: an area where fuel packages and/or sealed IBCs are group together in quantities greater than minor storage.

Road tanker: a tank vehicle approved under the ADG Code to transport fuel.

SDS: Safety data sheet for a hazardous chemical.

Further information

Standards Australia

Search for and buy Australian Standards such AS1940, AS1692 and AS/NZS60079:10.1.

Fuel suppliers and local distributors may be able to provide technical assistance regarding their products, including the provision of an SDS.

Last updated: 15 July 2018

Learn More ...

- Fuel Storage Register

- Fuel Storage

- Fuel Safety Data Sheets

- Fuel Suppliers Safety Data Sheet access and DOWNLOAD